Extra Heavy Duty

Latchbolt and deadbolt are fabricated from stainless steel

Internal parts are fabricated from high strength steel alloy

Mortise lock case and internal components are treated to ensure corrosion resistance

Lockcase can be reversed without disassembling the lock body

High strength steel alloy cylinder retainer

Two piece anti friction latchbolt reduces wear and tear

Hub blocking plate guards against spindle manipulation

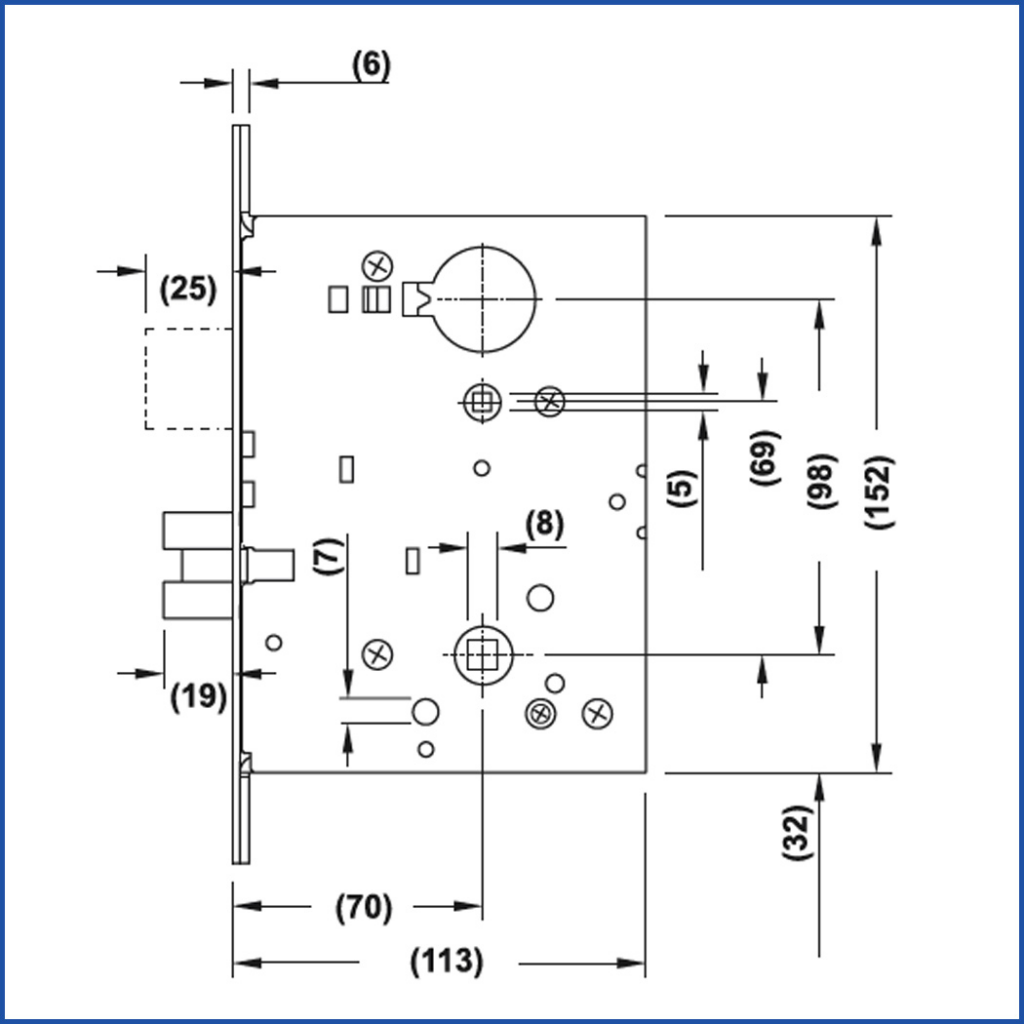

Case size 4-5/16” x 6” x 1” (110mm x 152mm x 25mm)

Armour Front 1-1/4” x 8” (32mm x 203mm)

Backset 2-3/4” (70mm) only

Preparation Conforms to ANSI A115.1

Door Range 1-3/4” (44mm). Specify if other door thickness required

Bevelled Doors Self adjusting tabs on case

Deadbolt 1” (25mm) throw, stainless steel

Latchbolt 3/4” (19mm) throw, with anti-friction tongue, stainless steel

Deadlocking Non-handed, stainless steel

Through Bolts Through bolted trim aligns with mortise lock case

Stop works Incorporated into thumbturn

Strike 1-1/4” x 4-7/8” Curved lip, square corner. Extended lip strikes available

Spindles Break-away under excessive torque. Preventing forced entry or lock damage

Cylinder 6 pin cylinder standard, with two keys, “C” keyway

IC Core Interchangeable Core (IC) available

Cam All cylinder functions use standard butterfly style cam

Cylinder Collar Compression ring and collar supplied standard

Fasteners Concealed under the rose or escutcheon

Standard Finishes Standard levers US32D (630), Designer levers US32D (630) and US15 (619)

Other finishes available. Extended lead time required